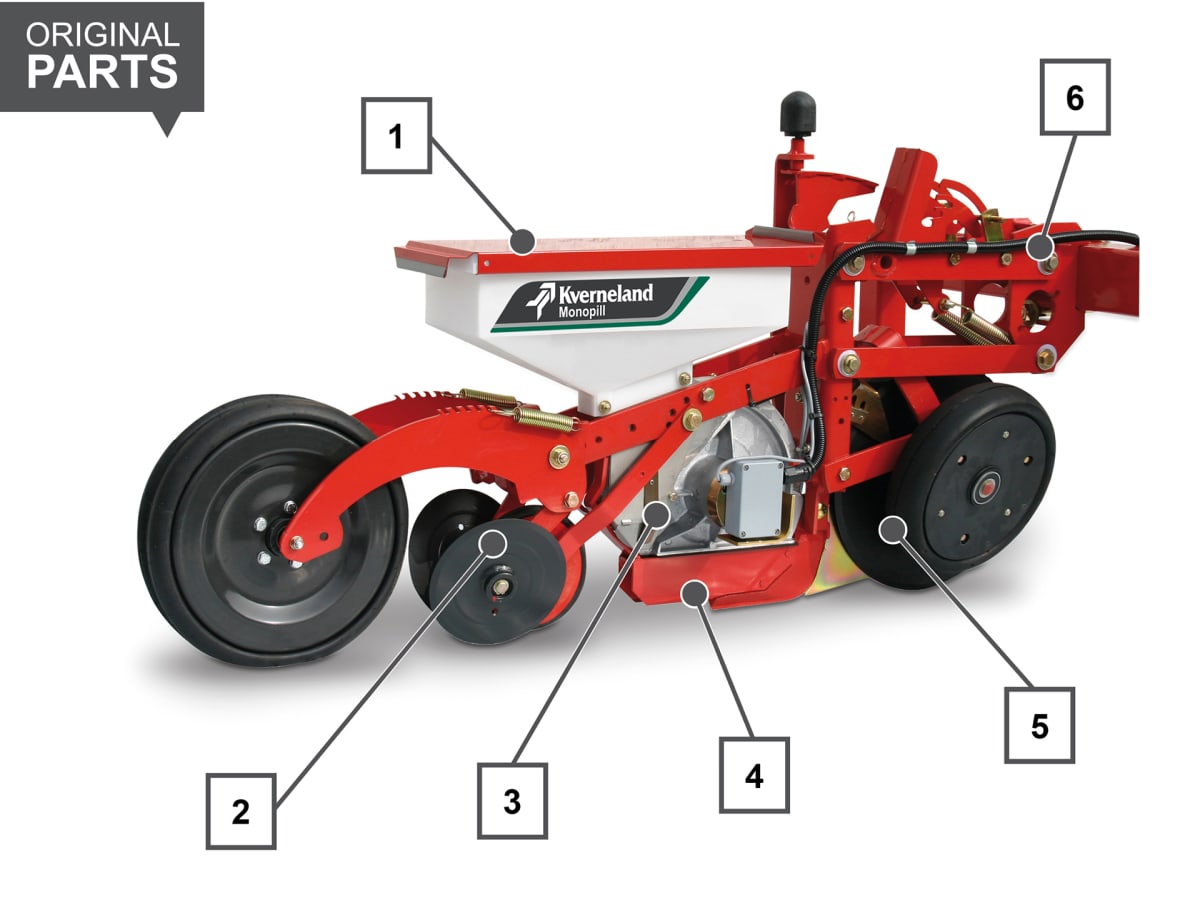

Monopill - get ready for next season

Helpful tips and tricks to get your Monopill sugar beet seed drill prepared to operate at its maximum capacity through the season.

Contact your local Kverneland dealer to arrange a pre-season service or health check on your Kverneland sugar beet seed drill to ensure it delivers the best performance and maximises crop yields.

Ensure all seed hoppers are clean.

Inspect covering discs and bearings.

Inspect and test seed discs and covers.

Check coulters for wear and any damage.

Inspect depth wheels, cutting discs and bearings.

Check for wear in the parallelogram pivot points.

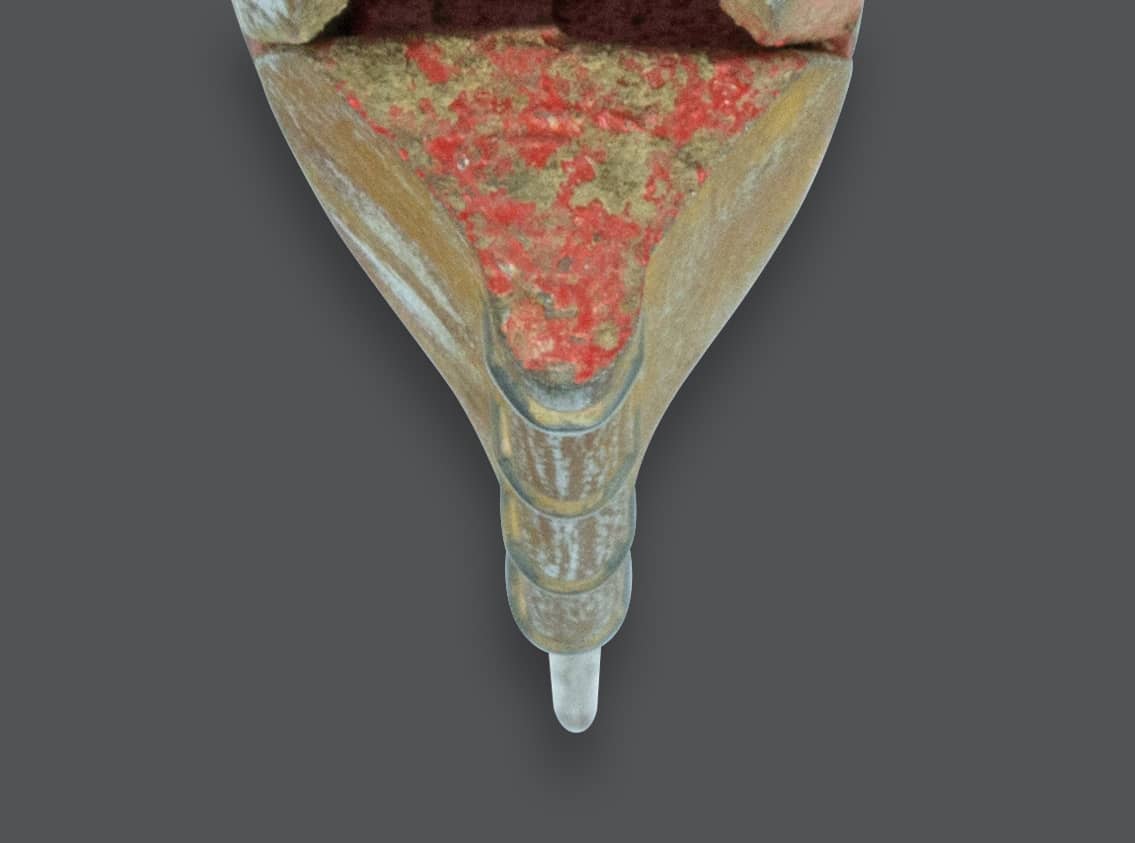

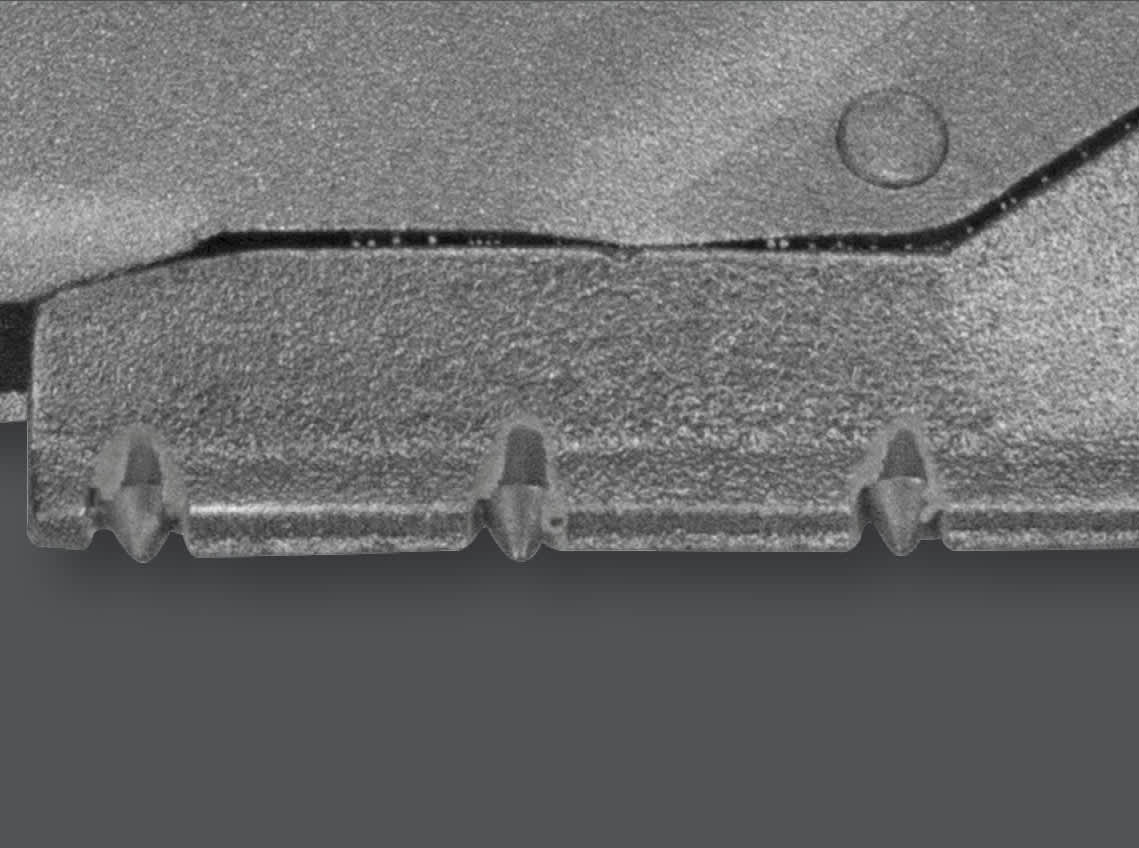

Our “New” Tungsten Carbide protected Mulch Seeding coulter adds extra efficiency and cost savings to your Monopil Precision seed drill.

The specially placed Tungsten Carbide Studs equally placed along the cutting edge gives 4 points of defence against stones and wear – guaranteeing smooth

performance and longer life time when compared to conventional coulters.

A139646886

The protected “Cutting Edge” delivers a constant depth and “V” furrow profile ensuring the seed remains where it is placed – resulting in consistent spacing,

germination and plant growth.

The well-used coulter still retains an intact V furrow profile.

Tungsten Carbide Studs for reduced wear.

The seed discs are the heart of the machine. Dependant on the seed being sown, each disc contains a number of “Seed Cells” that are designed to ensure consistent seed spacing and depth. Worn discs can result in irregular spacing, poor germination and reduced crop yields.

Ask your Dealer to test your seed discs today and replace them if they are worn.

The Monopill’s parallelogram linkage ensures a uniform depth and performance from all seed units in all conditions. Ask your dealer to check all pivot points and replace those worn with the Overhaul Kit.

PARALLELOGRAM KIT

A139140032

Sharp and serviceable cutting discs ensure the ground is cleanly cut enabling the seed coulter to penetrate the soil to produce a clean V shaped furrow. Likewise the rear soil covering discs guarantees the seedbed is evenly covered ensuring optimum seed protection and even germination.

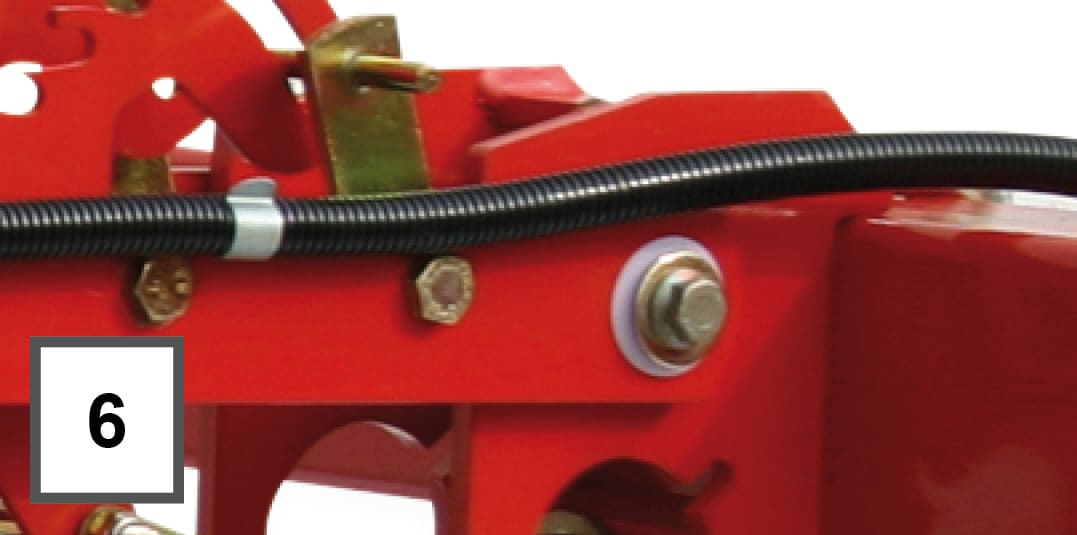

Hard ground conditions and deep sowing can apply added stress to the cutting disc bearings and which could result in increased wear. To protect this important area the overhaul bearing kit is now available.

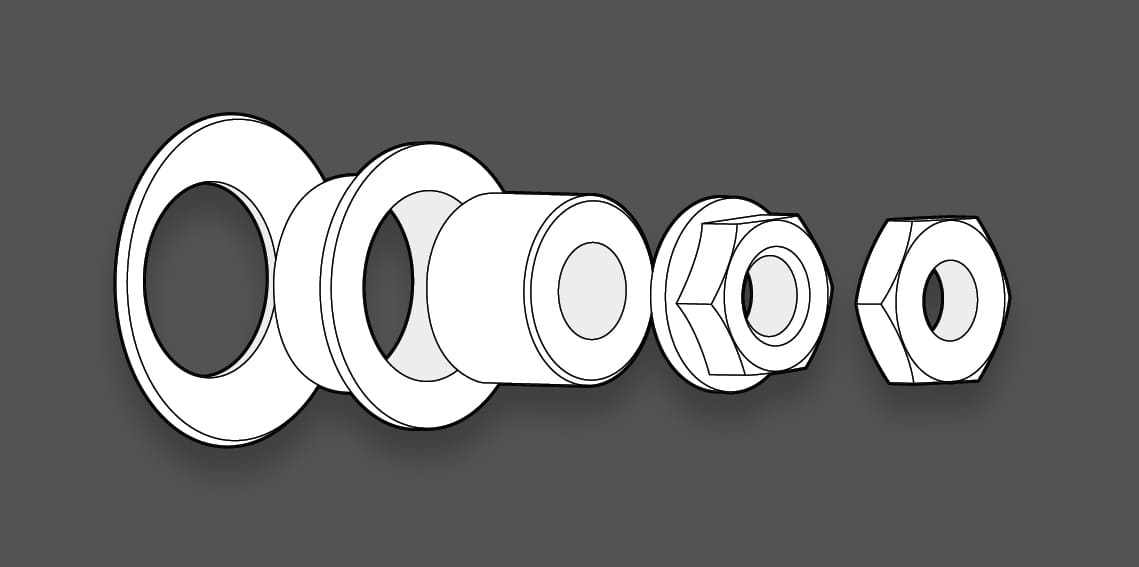

CUTTING DISC BEARING KIT

AC858093

1x Steel flange

1x Bearing

1x Safety Clip

Ask your dealer to check all cutting discs and bearings prior to the season and replace them if worn or damaged.

Time is money, and we know the importance of receiving the right parts at the right time! Your Kverneland dealer is supported by a massive distribution network to supply you with exactly what you need, when you need it.

Our main distribution centre Metz warehouse is located in Thionville, France. A strategic location for distributing parts to all corners of the world. With over 70.000 parts in stock and 24/7 service, we are ready to supply you with parts – at any time!